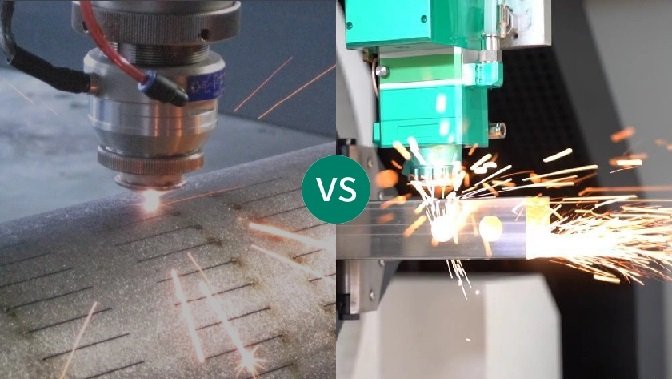

Fiber laser cutting machines are a revolutionary technology that has transformed the way we cut and engrave materials. In recent years, more and more industries are transitioning to fiber laser cut stainless steel sydney machines because of their incredible efficiency. Traditional cutting machines, on the other hand, are quickly becoming obsolete due to their limitations. In this article, we’ll explore why fiber laser cutting machines are more efficient than traditional cutters.

Table of Contents

The Science Behind Fiber Laser Cutting Machines

Fiber laser cutting machines use a laser beam that is generated by a solid-state source. The laser beam is then amplified and focused through a system of mirrors and lenses before it is directed to the material being cut. The laser beam is so precise that it can cut through the most intricate designs with ease.

Speed and Precision

Fiber laser cutting machines are incredibly fast and precise. They can cut through material at speeds of up to 1000 inches per minute, and they can cut with an accuracy of up to 0.0005 inches. This means that even the most complex designs can be cut quickly and accurately.

Versatility

Fiber laser cutting machines are incredibly versatile. They can cut through a wide range of materials, including stainless steel, aluminum, copper, brass, and more. Additionally, fiber laser cutting machines available at omni-cnc.com can be used to engrave and mark materials, which makes them ideal for a variety of industries, such as automotive, aerospace, and electronics.

Cost-Effective

While fiber laser cutting machines may have a higher upfront cost than traditional cutting machines, they are much more cost-effective in the long run. Because fiber laser cutting machines are so fast and efficient, they can cut through material in a fraction of the time that it takes a traditional cutting machine. This means that fewer labor hours are required, which results in lower labor costs.

Faster Turnaround Time

Fiber laser cutting machines are incredibly fast, which means that they can complete projects in a fraction of the time that it takes a traditional cutting machine. This faster turnaround time is a huge advantage for industries that need to produce large quantities of products quickly.

Advantages of Fiber Laser Cutting Machines Over Traditional Cutters

1. Faster cutting speeds: Fiber laser cutting machines are able to cut more quickly than traditional cutters, allowing you to complete projects in a fraction of the time.

2. More precise cuts: Fiber laser cutting machines are able to make cleaner, more precise cuts than traditional cutters, resulting in higher quality products.

3. Lower costs: Fiber laser cutting machines are more cost-effective than traditional cutters, resulting in lower overall production costs.

4. Reduced maintenance: Fiber laser cutting machines require less maintenance than traditional cutters, resulting in lower operating costs.

5. Greater flexibility: Fiber laser cutting machines are able to cut a wide variety of materials, allowing for greater flexibility in production.

Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines are used in a variety of industries, including the automotive, aerospace, medical, electronics, and jewelry industries. They are used to cut and engrave a variety of materials, including metals, plastics, stone, and glass. These machines are capable of cutting and engraving complex shapes and designs with high precision and accuracy. Fiber laser cutting machines can also be used for marking, which can be used to label items with serial numbers, logos, and other markings.

The Bottom Line

In conclusion, fiber laser cutting machines are more efficient than traditional cutters because they are faster, more precise, more versatile, cost-effective, and have faster turnaround times. While traditional cutting machines may still have a place in certain industries, more and more industries are transitioning to fiber laser cutting machines because of their incredible efficiency and versatility.